Stainless steel is a cornerstone material in modern industries, prized for its durability, corrosion resistance, and versatility. Among the various grades of stainless steel, Stainless Steel 304 stands out as one of the most popular and widely used options. From chemical processing to food production, this material meets the demanding requirements of numerous applications. In this article, we delve into the properties, composition, and uses of stainless steel 304 plates and how they compare with other specialized stainless steel grades like 310S.

What is a Stainless Steel 304 Plate?

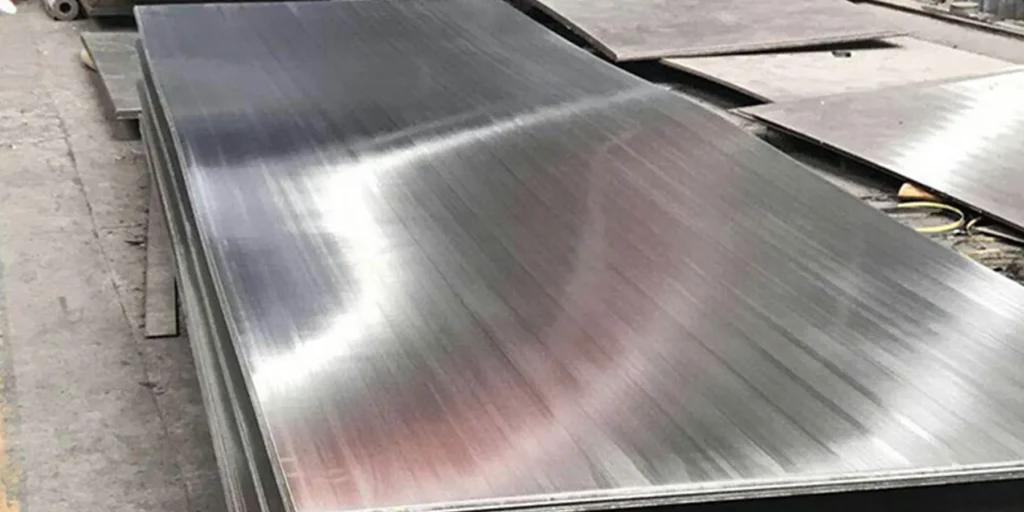

A Stainless Steel 304 Plate is a flat, thin sheet made from 304 stainless steel, characterized by its high chromium and nickel content. This alloy is known for its exceptional resistance to corrosion, excellent formability, and impressive mechanical properties. The 304-grade stainless steel is versatile and reliable, making it ideal for applications ranging from construction and manufacturing to food processing and medical equipment production.

Properties of Stainless Steel 304 Plate

Stainless Steel 304 Plates offer a range of beneficial properties that make them highly suitable for various industrial uses:

- Corrosion Resistance: The high chromium content (18-20%) in stainless steel 304 creates a passive layer on the surface, protecting it from corrosion in various environments, including acidic and chloride-rich conditions.

- Strength and Durability: With a tensile strength of approximately 515 MPa and yield strength of 205 MPa, the 304-grade is robust and able to withstand considerable stress without deformation.

- High-Temperature Resistance: Stainless steel 304 maintains its structural integrity even at high temperatures, making it suitable for applications where temperature stability is crucial.

- Hygienic Properties: This steel grade is non-porous and easy to clean, making it ideal for applications in food processing and healthcare industries where hygiene is paramount.

- Good Weldability: It is easily weldable using standard fusion and resistance methods, which broadens its application scope in construction and manufacturing projects.

Composition of Stainless Steel 304 Plate

Stainless steel 304 is austenitic, containing iron, chromium, and nickel as primary components. The typical composition includes:

- Chromium (Cr): 18-20%

- Nickel (Ni): 8-10.5%

- Iron (Fe): Balance

- Carbon (C): ≤ 0.08%

- Manganese (Mn): ≤ 2%

- Silicon (Si): ≤ 1%

- Phosphorus (P): ≤ 0.045%

- Sulfur (S): ≤ 0.03%

The presence of chromium and nickel enhances corrosion resistance and mechanical strength, while small quantities of carbon, silicon, and manganese provide structural stability and resistance to wear.

Uses of Stainless Steel 304 Plate

The versatility of stainless steel 304 plates makes them suitable for a wide array of industrial applications:

- Chemical Processing Equipment: Due to its resistance to various chemicals and high temperatures, 304 plates are used for manufacturing chemical tanks, piping systems, and processing equipment.

- Food and Beverage Industry: Its hygienic properties make stainless steel 304 plates ideal for food processing equipment, kitchen countertops, and storage tanks.

- Construction and Architectural Applications: Used in building facades, roofing, and structural components due to its aesthetic appeal and corrosion resistance.

- Manufacturing and Machinery: Utilized in the production of machinery components, automotive parts, and general manufacturing equipment.

- Medical and Pharmaceutical Equipment: The alloy’s biocompatibility and easy-to-sanitize surface make it perfect for surgical instruments, sterilizers, and other medical equipment.

Comparison with Stainless Steel 310S

While stainless steel 304 is known for its general-purpose utility, Stainless Steel 310S is a specialized alloy that is preferred in extreme environments:

- Higher Temperature Resistance: Stainless steel 310S is designed to withstand much higher temperatures compared to 304, making it suitable for furnace components, heat exchangers, and other high-temperature applications.

- Enhanced Corrosion Resistance in Severe Conditions: With its higher chromium and nickel content, 310S provides superior resistance against oxidation and sulfidation in highly corrosive and high-temperature environments, such as chemical processing plants.

Advantages of Stainless Steel 304 Plate

Stainless steel 304 offers a range of advantages over other materials:

- Durability: It withstands wear and tear, ensuring long service life.

- Corrosion Resistance: Performs well in both ambient and elevated temperature environments.

- Low Maintenance: Requires minimal maintenance due to its smooth surface, reducing operational costs over time.

- Aesthetic Appeal: Offers a modern, shiny appearance suitable for decorative applications.

- Recyclability: Stainless steel 304 is 100% recyclable, making it an eco-friendly choice for sustainable projects.

Conclusion

Stainless Steel 304 Plates are a fundamental material in industries due to their balanced properties of strength, durability, and corrosion resistance. Their widespread usage in manufacturing, construction, food processing, and chemical handling highlights their versatility. Compared to other specialized grades like 310S, stainless steel 304 remains a cost-effective choice for applications that do not involve extreme temperatures or highly corrosive environments. As industries continue to evolve, the dependable nature of stainless steel 304 will ensure its continued prominence in meeting the demanding needs of modern applications.